Info on Laser Engraving

Laser Engraving Systems work with the same principles as a normal printer. Just like you do with an inkjet. We set the page size to the size of the piece with which we are working. Next, we import your image and place it on the setup page corresponding to the engravable area where we want to etch the item. Next, we then add any text or any other setup change that is required. Then we send it to print on the laser.

Alpha Trophies have added a new Laser Engraving System to existing equipment. We can offer more customisation services and expand the product line for our customers.

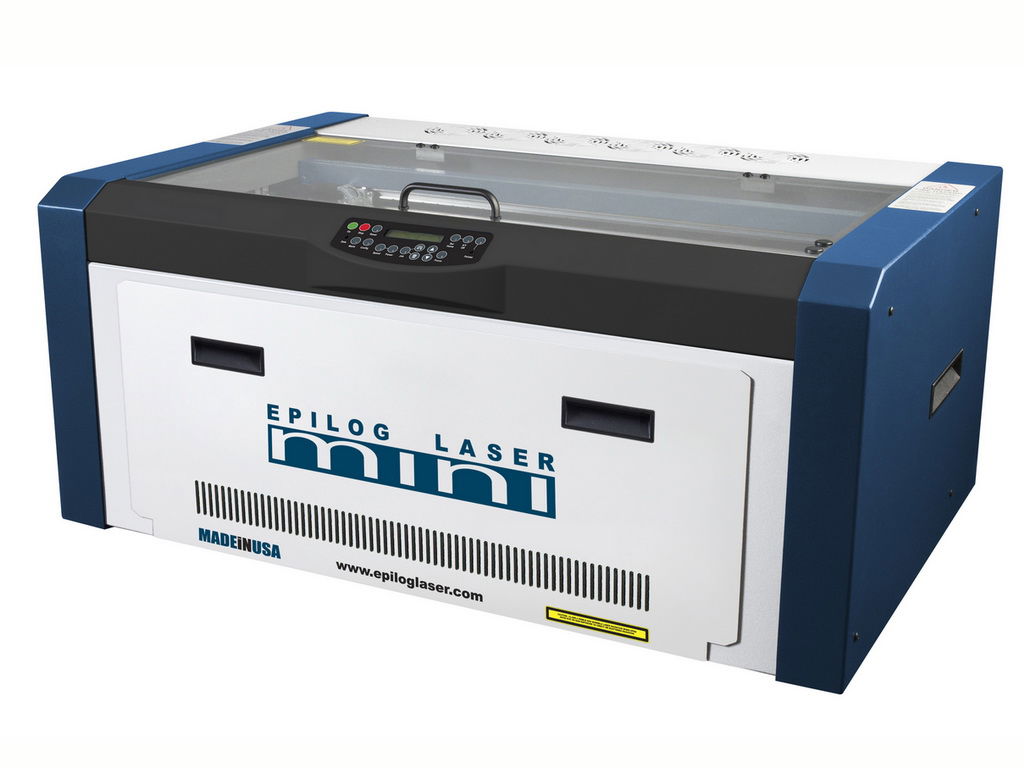

Alpha Trophies of Edinburgh, a leading provider of award and engraving services, today announced the company has incorporated an Epilog Laser (mini 24 model) engraving/cutting system into its current operations.

The addition of this cutting-edge technology will help the company provide more specialised award and engraving options for customers.

“We are thrilled to have brought a laser system on board,” said Alan the company director.

“This equipment allows us to provide the highest-quality customisation services for our customers.”

With the ability to work on a variety of materials including acrylic, wood, fabric, plastic, glass and more, the laser equipment allows Alpha-Trophies to easily and quickly customise plaques, awards, gifts, electronics, and other items for customers.

“From traditional awards and plaques to customising laptop covers and other electronics, we’ll be able to provide our customers with the most detailed engraving results,” said Alan. “The versatility and convenience of the laser system help us provide better products and services to our customers.”

See our sample gallery of previous laser-engraved items here: